Hollow-Fibre Ultrafilter

Basic Info

| Model NO. | CL |

| HS Code | 842230 |

| Production Capacity | 10000 pcs/year |

Product Description

:It is used for making mineral water, organic objects, microorganism, colloids, micro-granules, etc. That are not eliminated by the previous filters in the water will be thoroughly eliminated. But the healthful microelements in the water are reserved.

Characteristics:

Advanced membrane separating technology is used. The ultra-filter adopts dissymmetrical semi-permeable film which is made from macromolecule material with special process. The raw liquid flows under pressure, inside or out side the film. The macromolecule substance and colloid particles in the raw liquid are clogged at the film surface and are brought away by circulating wraw liquid. Then the raw liquid becomes inspissated, and further more, the substance in liquid is separated, concentrated.

| Model: | Cl-2 | CL-3 | CL-4 | CL-5 | CL6 | CL-8 | ||||

| Capacity:t/h | 2 | 3 | 4 | 5 | 6 | 8 | ||||

| Filling Pressure: | < 0.2Mpa | |||||||||

| Suit water | Mineral water | |||||||||

| Size: L×W×H (mm) | 1100x800x1600 | 1100x800x1600 | 1500x800x1600 | 1550x800x1600 | 1600x800x1600 | 1800× 800× 1600 | ||||

| Total Weight:(kg) | 200 | 280 | 32 0 | 380 | 400 | 420 | ||||

Automatic Pet Bottle Liquid Pure Drinking Mineral Water Bottling Machine / Carbonated Flavored Soft Drink Juice Filling Labeling Packing Plant

What is the cost of water filling machine?How do you fill a machine with water?

What is automatic filling machine?

How do I choose a liquid filling machine?

¿Cuál es el costo de la máquina de llenado de agua?

¿Cómo se llena una máquina con agua?

¿Qué es la máquina de llenado automático?

¿Cómo elijo una máquina de llenado de líquidos?

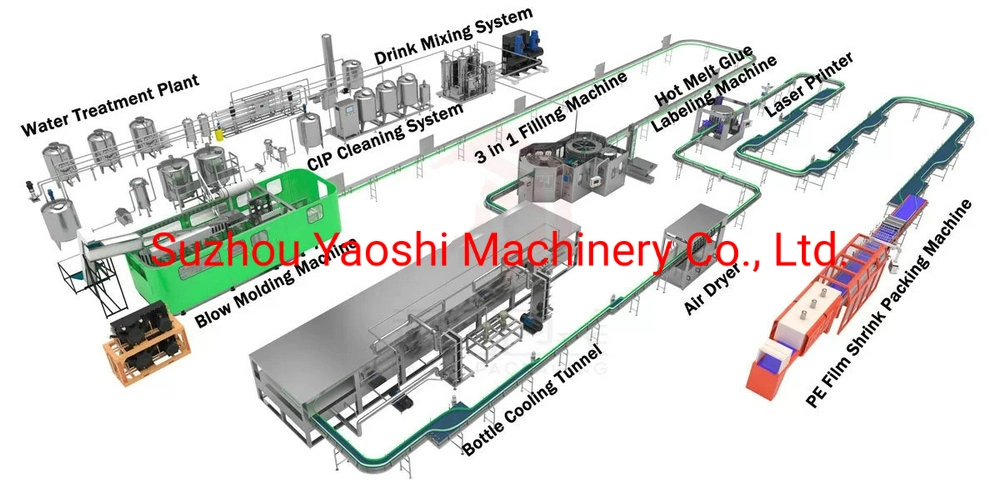

*We supply complete solution for the water filling plant ,including

Water treatment system / Washing filling capping machine / Code sprayer / Automatic labeling machine / Automatic packing machine / Automatic Palletizer system

The Complete Bottled Mineral Water / Pure Water Production Line used in the beverage filling operations. The three functions of bottlewash, fill and seal are composed in one body of the machine. The whole process is automatic.

Parts List:

| Item | Parts Name | Brand | Brand from |

| 1 | PLC | SIEMENS- | Germany |

| 2 | Inverter | SIEMENS- | Germany |

| 3 | Touch Screen | SIEMENS- | Germany |

| 4 | Switch | Schneide | France |

| 5 | Contactor | Schneide | France |

| 6 | Relayer | Schneide | France |

| 7 | Solenoid Valve | FESTO- | Germany |

| 8 | Drive Motor | SEW EURODRIVE | Germany |

| 9 | Reducer | SEW EURODRIVE | Germany |

| 10 | Water Pump | GRUNDFOS- | Denmark |

| 11 | Main Bearing | SKF- | Sweden |

| 12 | Sensor | SICK | Germany |

| 13 | Air Component | FESTO- | Germany |

| 14 | Stainless Steel Frame | POSCO | Korea |

| Air Conveyor. - Air conveyor is fixed on the floor, with fan installed on the top.- Air filter is positioned at every entrance of air fan, to prevent dust blown into bottles.- Bottles are held on the neck in the conveyor and transported into filling machine by blowing power.- All are made of stainless steel SUS 304 /316.- Rack made by high quality carbon steel welded. Flat Conveyor.- Energy saving. High efficient. Adapt to customer factory layout- Special lubrication system, keep products clean, health, safety- Extended service life- Electric eyes design keep whole line running safety and quickly- Overload protection mechanism to effectively ensure the safety of the machine |

Bottle Washing. - Into bottle way is air conveyor direct connection with bottle dial. | |

| Bottle Filling - 304/316 Stainless steel high precision filling nozzle - Filling volume adjustable in fine rank, same liquid level after filling - All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean - 304/316 stainless steel filling pump - Efficient spray nozzle rinse thoroughly and save water for flushing | |

Bottle Capping. - Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping - No bottle no capping - Automatic stop when lack of bottle |

The Turnkey project need :

| I. Water Treatment System Different water sources with different equipmentRaw water pump: Silica sand filter: Active carbon filter:chlorine content Sodium ion exchanger (softener):Precision filter: Reverse osmosis: UV: Ozone: Finished water tank: |

|

| Bottle Blowing Machine The complete set contains: Main automatic blowing machine high &low pressure compressor high pressure air storage tank air filters air cooling dryer water chiller Bottle mould follow the sample to design | |

| Bottle washing filling and capping 3in1 monoblock machinery Air conveyor --washing part --filling part --capping part--light checker --filled bottle conveyor Laser code printer PVC sleeve shrinking labeling machine : Material of Label: PVC,PET,OPS,this is used most in the drink industry ,capacity could be 1000-28000bph OPP labeling machinery This is new and popular machinery ,label cost is cheaper than PVC, but most large drink factory chooses itShrink wrapping packing machine Or: Carton packing machinery |

1. The guarantee of our machines is 5 years, life-long services, also we will supply spare parts along with the machines free of charge, the parts will be enough for at least 3 years for the normal operation of machine.

2. Trainning: We can train your engineers in our factory free of charge. IMeans you can send your engineers to our factory to study and training, we have rich experiences for the training, it is the good way to make sure that you can operate and maintain our machines successfully and for long time normal use.

3. Checking We will supply you detail user manual for our machines, also we will make one Video CD to show you how to install and maintain the machines, it will help you to maintain the machines for the long time.

4. Installtion We will send our engineers to your factory to install the machines and train your staff how to operate the machines., We have been doing the install jobs for our overseas customers for many years.

5. Spare parts:We will help to arrange the shipping of goods for you and keep you posted about the steps.